CATALOGUES

Below you can download the catalogues in pdf-form of our standard cylinders and standard components.

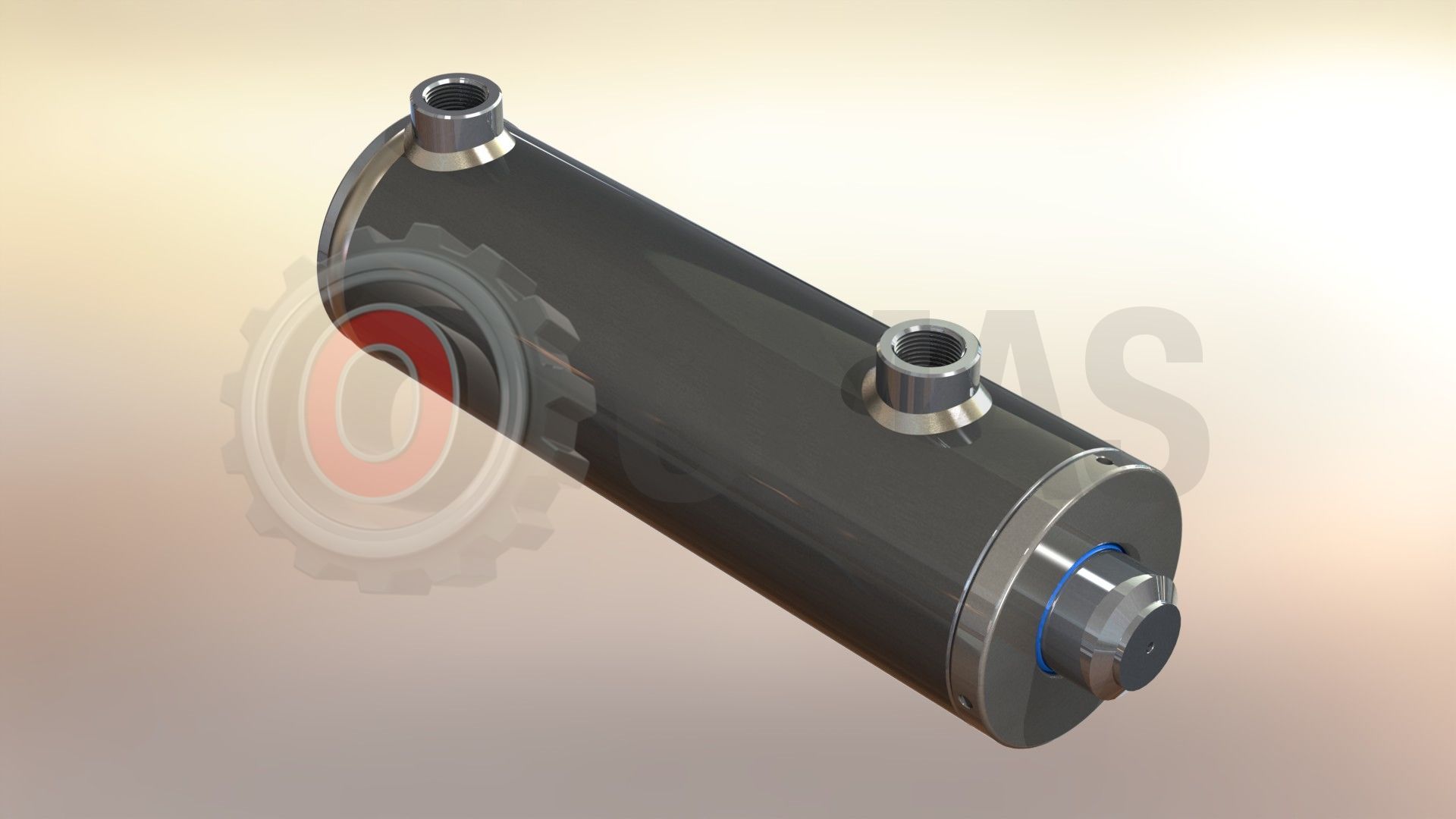

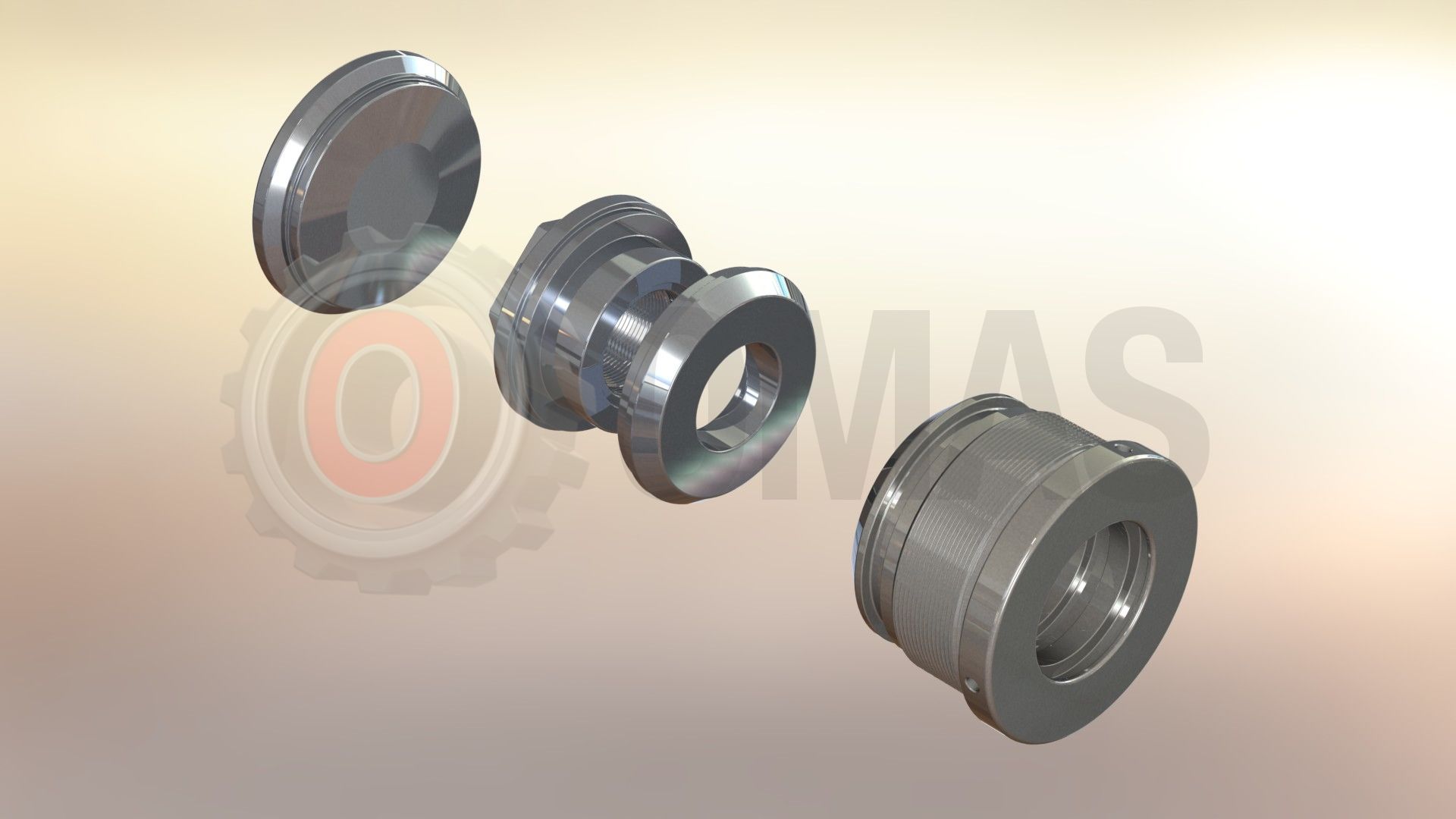

However, we have the possibility to build hydraulic cylinders and/or components for hydraulic cylinders to sample and to customer’s drawing, starting from a single piece up to hundred pieces using the materials and treatments below.

MATERIALS

These are the main materials used for the construction and the repair of hydraulic cylinders for our customers

| Materials for liner and chromed stem * | Materials for components | Gasket materials | Surface treatments |

|---|---|---|---|

| 20MNV06 | Hardened steel 42CRM04, 38NCD4 | Epdm | Cementation |

| 42CRM04 | Steel C40/C45 | Epdm Fda | Dacromet |

| 42CRM04 hardened | Manganese alloyed steel 11SMn30 | H-Nbr | Phosphating |

| Stainless steel AISI 304L | Structural steel S355J2G3 EN10025-2 | Nbr | Geomet |

| Stainless steel AISI 316L | Aisi 304 | Nbr 95 | Chemical nickel plating |

| Nickel-plated steel | Aisi 316L | Nbr Fda | Nitrex |

| C40/C45 | Arnite | Peek | Nitroxidation |

| C40/C45 hardened | Bronze | Pom | Nitrotec |

| Internally polished tube | G25 | Ptfe | Nitration |

| Internally wire-drawn tube | GJS 400 | Ptfe carbone | Neutral anodic oxidation |

| Internally rolled tube | GJS 500 | Ptfe glass | Shot blasting |

| Inconel | Pu | Induction hardening | |

| Brass | Fda silicone | Ceramic treatment | |

| Ptfe | Viton | Painting | |

| Nickel super alloys | Dip galvanization | ||

| Trivalent galvanization |

* For all this materials can be required a resilience certificate -20° /-40° and a possible ultrasonic control according to customer specification.